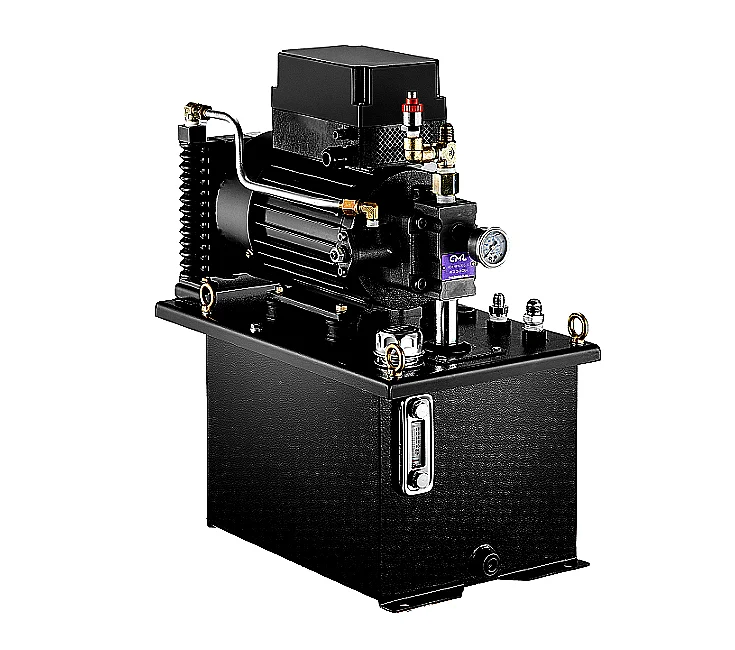

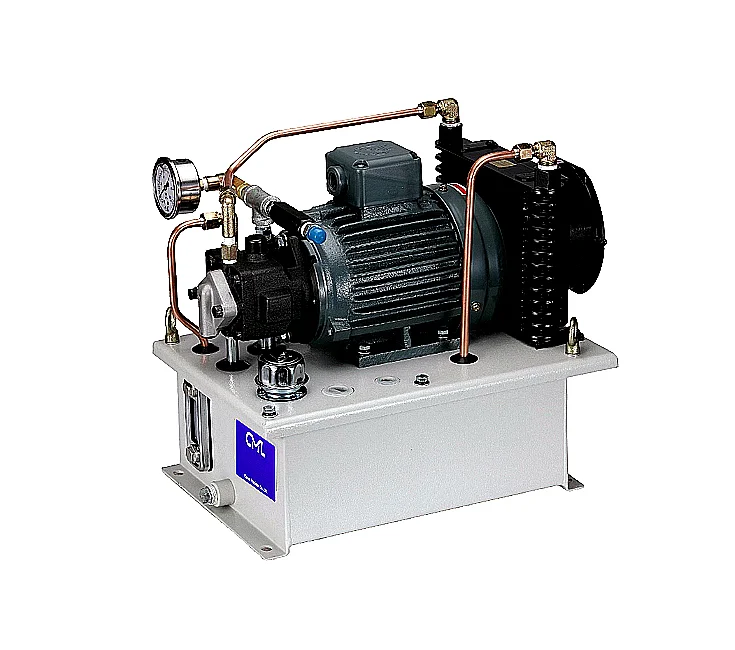

Customized Power Unit

CML power unit, hydraulic station, hydraulic pump stations, pump stations, hydraulic powerpack

Camel Precision Co., Ltd.(CML) has 40 years’ experience in designing customized power units for customer, and has customized service processes and power units designed for different needs, such as compact vane pump power unit (NPU) and power unit with cooling circulation pump (SPU). By utilizing the characteristics and patented design of oil pumps, we can make clever use of space and combine them with other hydraulic valves to achieve space-saving and stable oil temperature. CML is a good selection for you to choose the power unit, please contact CML staff for any request.

Power unit customized process

Phase 1: Development

CML collects customer requirements, applications, outlines ideas, conducts specification discussions and cost evaluations. After customer agrees to the preliminary cost and confirms the required specifications, the design is drawn and finalized through close communication and consensus.

Phase 2: Production

After the samples are made and tested by both parties, according to the test report, proper adjustments would be made such as to add or remove functions, and then tested again after the modifications are made. When the products are finalized, CML and the customers will work together to set the acceptance standards for the shipped products and the packaging method for bulk shipments to avoid damage during the shipping process.

Phase 3: Testing

CML provides advice on installation and settings, checks the operating performance and numbers when the products sent to the customer (when installed in the machine or connected to the machine's hydraulic circuit), confirms that the products is running normally, and receives a reply from the customer confirming receipt of the product, and then later on follows up on satisfaction and collects feedback from the customer.

Phase 4: After sales service

If customer has question about products, we will ask customer to provide product information including images, videos, audio files, etc., and initially determine whether the data content can be removed instantly; if the customer cannot remove problems directly, we will check product’s type and region, and assess the feasibility of on-site testing or send the product back at the factory; CML will determine the situation and the cause of occurrence, provide suggestion and perform follow-up solution.

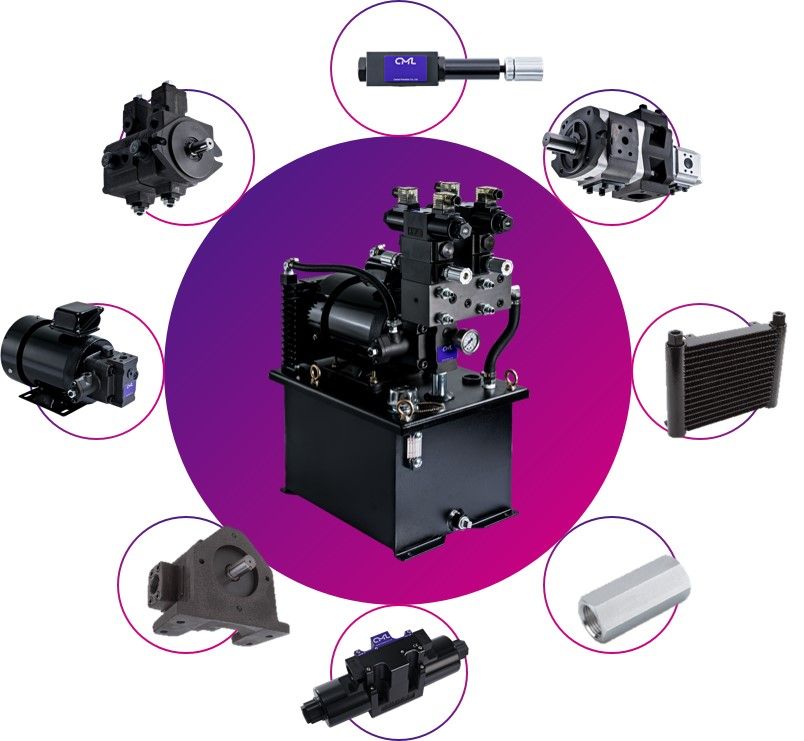

Power unit with components:

- Motor, Oil Pump:Provide driving force for the hydraulic system, oil pumps can be vane pumps (variable vane pump, fixed pump); gear pumps (internal gear pump, external gear pump).

- Solenoid Directional Control Valve:Also known as wet type solenoid valve, control the direction of flow of hydraulic oil in the system, and change the direction of movement of the hydraulic cylinder.

- Relief Valve:There are two types of relief valve namely as solenoid relief valve and hydraulic relief valve. Commonly seen in power units with solenoid relief valve, with the solenoid valve and circuit design, a variety of uses stacked to achieve space-saving effect. The main function of the relief valve is to prevent the entire hydraulic system from overpressure, equivalent to a safety valve, protect the safety of the pump and the oil system, maintaining a constant pressure of the hydraulic system.

- Check Valve:Usually installed in the oil pump outlet, when the machine stops to prevent the hydraulic oil backflow, resulting in the system motor, oil pump will instant reversal.

- Pressure Reducing Valve:Suitable for a system requiring different pressure applications, and has two (or more) hydraulic circuit pressure needs.

- Flow Control Valve:In the hydraulic system, you can change the flow rate of the circuit pressure oil, allow to change the hydraulic motor or hydraulic cylinder movement speed, and the flow rate able to limit the flow.

- Filter:According to the circuit design of the power unit, there will be two filter ports in the oil tank. One is installed at the suction inlet/outlet of the oil pump to avoid impurities in the hydraulic oil of the tank. Another one is installed in the hydraulic oil return line of the system to ensure the quality of the hydraulic oil returned to the tank from the hydraulic cylinder or operating line of the machine. The other one is installed in the hydraulic oil return line of the system to ensure the quality of the hydraulic oil returning to the tank from the hydraulic cylinder or operating line. There is a differential pressure alarm device on the piping system, when the filter is clogged, it can be visually or by telecommunication number to indicate the alarm, then the filter should be cleaned or replaced.

- Pressure Gauge:Used to display the working pressure of the hydraulic station, in order to facilitate the user to view the pressure.

- Oil Level Meter:As the name suggests, in order to view the scale of hydraulic oil in the tank tool, which installed on the side of the tank and show real-time display of hydraulic oil level.

- Temperature Gauge:Depending on the demand and display the temperature of the hydraulic oil.

- Air-Cooled Radiator:Through the cooled radiator to effectively suppress the temperature rise, the hydraulic parts and hydraulic oil can extend the service life, is an indispensable part of the power unit to stabilize the oil temperature.

Customized Power Unit | CE & ISO Approved Hydraulic Solutions | Trusted by Industry Leaders – CML

Located in Taiwan since 1981, Camel Precision Co., Ltd. is a Customized Power Unit manufacturer in Machinery and Equipment Manufacturing Industry.

In 1981 Camel Precision Co.,Ltd was founded. The management of company fully awards of high quality products requires not only sophisticate machinery, But good knowledge in technology is also important as well. Company invited senior engineers from Germany and Japan to lead the manufacturing and training of local engineers in hydraulic industry. We offer our customers industrial pumps, solenoid directional control valves, hydraulic pumps, vane pumps, external gear pump, internal gear pump, directional valve, hydraulic valves...etc.

CML, Camel Hydraulic, Camel Precision has been offering customers high-quality Vane Pump, Variable Displacement Vane Pump, Internal Gear Pump, Eckerle Asia Agent, External Gear Pump, Solenoid Valve, Modular Valve, Pressure Reducing Valve, Flow Control Valve, Hydraulic Valve since 1981, both with advanced technology and 38 years of experience, CML, Camel Hydraulic, Camel Precision ensures each customer's demands are met.

Company Facts in Numbers

0

Years of industry experience

0

Number of clients served

0%

Customer repurchase rate