Production & Equipment

Preventive Quality Control is the benchmark of CML's quality policy, and it is implemented in every detail and process of the manufacturing through systematic and digital control, to achieve the quality optimization.

Intelligent Automation Monitoring System

Production machines are monitored and controlled in real-time through the Internet and presented on a visual panel. The monitoring system info includes output, yield, machine condition, and equipment efficiency analysis; visual management is used to effectively grasp the factory production status and timely solve abnormal problems, thus production capacity can be promoted.

Automated Testing

Automatically test and archive the hydraulic oil temperature and digitized production history data. Through temperature rise and multi-module test data, automatically determine and record production quality, quantity, and yield rate.

Automated Machining and Production Equipment

Automated Machining Production Systems offers three major advantages - intelligent process control, real-time numerical monitoring, and data cascading analysis - to effectively enhance workplace safety, speed mold changing, and improve process stability.

Production & Equipment | Award-Winning Hydraulic Pumps & Valves – CML: Certified, Trusted, and Proven Worldwide

Located in Taiwan since 1981, Camel Precision Co., Ltd. is a hydraulic pumps and hydraulic valves manufacturer in Machinery and Equipment Manufacturing Industry.

In 1981 Camel Precision Co.,Ltd was founded. The management of company fully awards of high quality products requires not only sophisticate machinery, But good knowledge in technology is also important as well. Company invited senior engineers from Germany and Japan to lead the manufacturing and training of local engineers in hydraulic industry. We offer our customers industrial pumps, solenoid directional control valves, hydraulic pumps, vane pumps, external gear pump, internal gear pump, directional valve, hydraulic valves...etc.

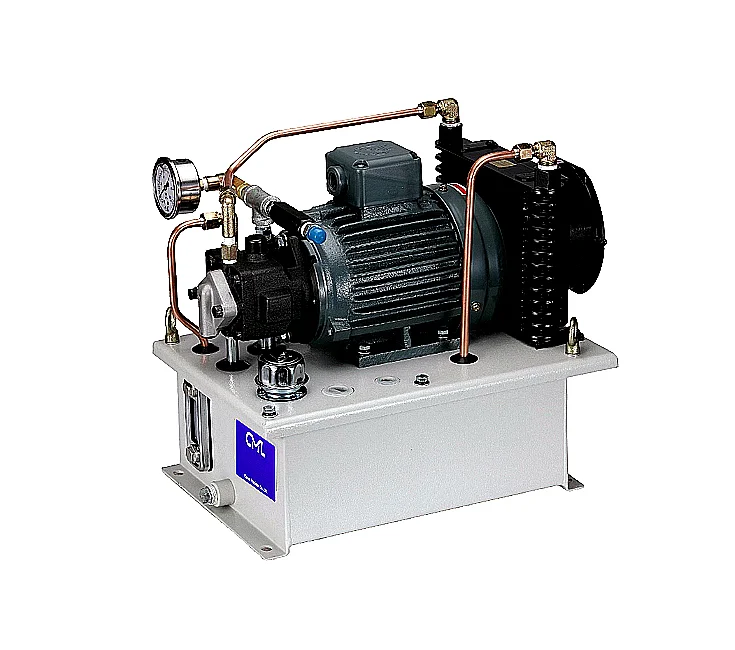

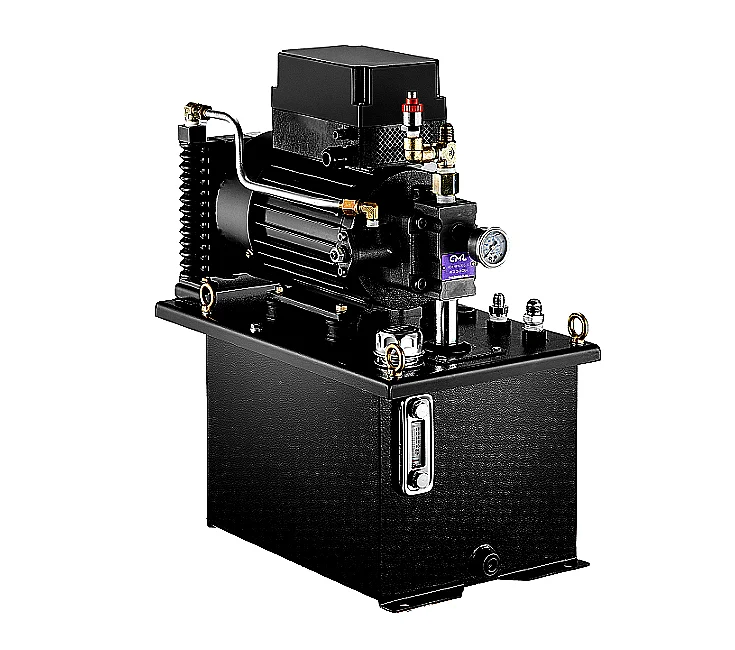

CML, Camel Hydraulic, Camel Precision has been offering customers high-quality Vane Pump, Variable Displacement Vane Pump, Internal Gear Pump, Eckerle Asia Agent, External Gear Pump, Solenoid Valve, Modular Valve, Pressure Reducing Valve, Flow Control Valve, Hydraulic Valve since 1981, both with advanced technology and 38 years of experience, CML, Camel Hydraulic, Camel Precision ensures each customer's demands are met.

Company Facts in Numbers

0

Years of industry experience

0

Number of clients served

0%

Customer repurchase rate