CML X Eckerle

Camel Precision Co., Ltd. (CML) is the sole agent of Eckerle in Taiwan and mainland China in Asia, CML and Eckerle have held a great cooperation relationship for more than twenty years since 2001. CML Taiwan office is located in Taichung, which is able to meet the requirements of both Northern and Southern Taiwan instantly. On mainland, CML owns three branches, Nanjing, Dongguan and Wuxi, that provide instant localized services. CML’s groups are experienced and owns full industrial information, which is your best choice for purchasing Eckerle pump in Asia.

Cooperation Milestone

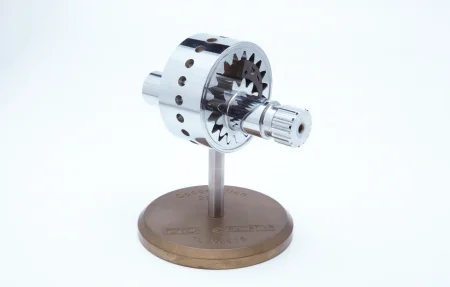

Eckerle was founded in 1935 in German, managing Hydraulic and Electronic products. Until now, not only strived to improve hydraulic pumps with better performance but also devoted to generating customize products and providing comprehensive solutions. CML and Eckerle's cooperation begin at the German exhibition in 1981. Over the past few years, CML and Eckerle have improved the operation technology of internal gear pumps through continuous interaction and also assist Eckerle to adjust the EIPC series which is suitable for injection molding machine. Eckerle’s internal gear pumps promote and sell in Taiwan and Mainland China, with an average annual sales volume of ten thousand units. The photo on the left is a monument presented by Eckerle in 2017 to commemorate the 15 years of cooperation between CML and Eckerle. Over 20 years of cooperation will continue and present more leading products and services

Origin of CML x Eckerle

In 1948, Eckerle produced the first high-pressure and high-performance internal gear pump in the world. The unique internal gear structure reduces malfunctions and internal leakage caused by wear and tear. The advantages of high efficiency and low noise make the operating environment more comfortable, and with a number of patented designs, it is the most competitive and widely used product in the selection of pump types.

In 1981, CML successfully developed the first internal gear hydraulic pump, and actively promoted the field of hydraulic servo energy saving systems, matching with the servo systems of famous international brands such as Siemens of Germany and Toshiba of Japan to maximize the benefits of servo-hydraulic energy saving. In the assembly of new machines or the modification of old machines, the energy saving effect can reach 50%, even 70% or more.

Asia Cooperation project

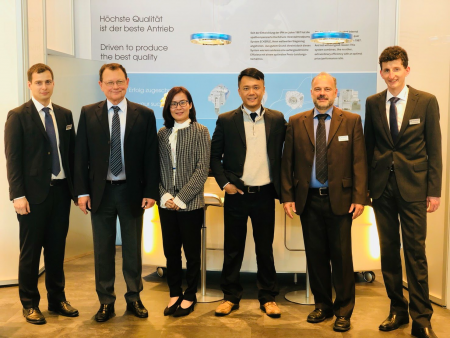

In 2002, Eckerle signed a cooperation plan with CML, and CML became the sole agent in Taiwan and China , which not only injected new opportunities for manufacturing technology in the domestic market, but also demonstrated CML's intentions and strength in the industry.

This cooperation will not only lead to efficient market expansion and gain more orders, but also achieve cost savings and create a win-win situation in marketing. With the mutual understanding of continuous product research and development, technology development and experience guidance, both parties can enhance the overall level and competitiveness of the pump industry and inject new vibrant into the market.

Cooperation pattern

During the past twenty years, Eckerle has been working with the CML to transform Eckerle’s brand culture into a suitable operating pattern in the environment for the Taiwanese and Chinese environments to reach a consensus. In addition to some business cooperation, we also have a strong personal relationship. Due to the close industrial property between CML and Eckerle, we are able to communicate with each other first-hand in terms of market and technical knowledge. Both companies also maintain a positive attitude in order to respond to customer needs and share a common philosophy and management philosophy, which is one of the reasons why CML and Eckerle have been working together for so long.

Uniqueness of Eckerle Internal Pump

Eckerle Eckerle internal gear pumps have been in production for over 40years experience, the most unique part is that they have a compensating structure inside. Initially, it was a one-piece structure, but through continuous improvement, research and development, the product was upgraded to a two-piece type. The compensation effect of the two-piece type is much better, and the number of customers and industry groups has been increasing as we continue to improve. At present, the servo energy saving in the injection molding machine market has a good efficiency. The compensating internal gear pump is not only the internal gear structure, but also able to change the parameters inside to match the customer's custom service.

Application:

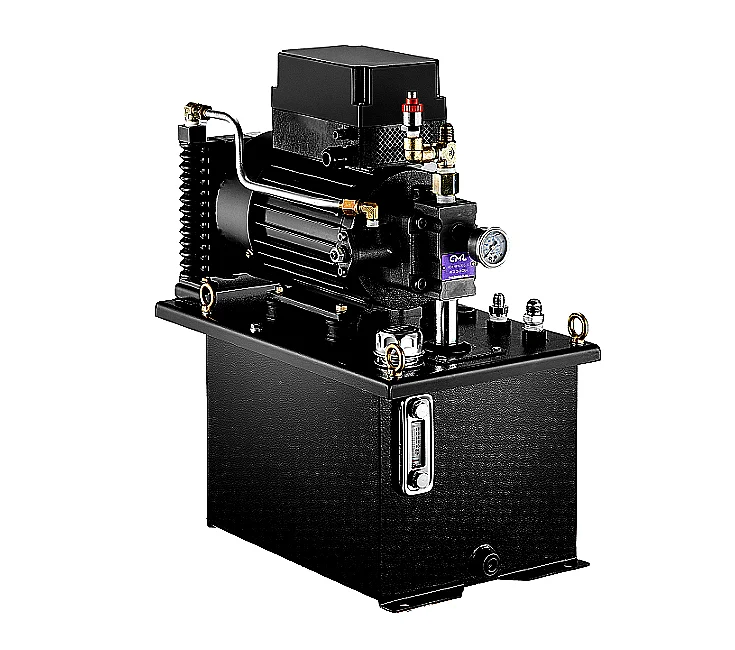

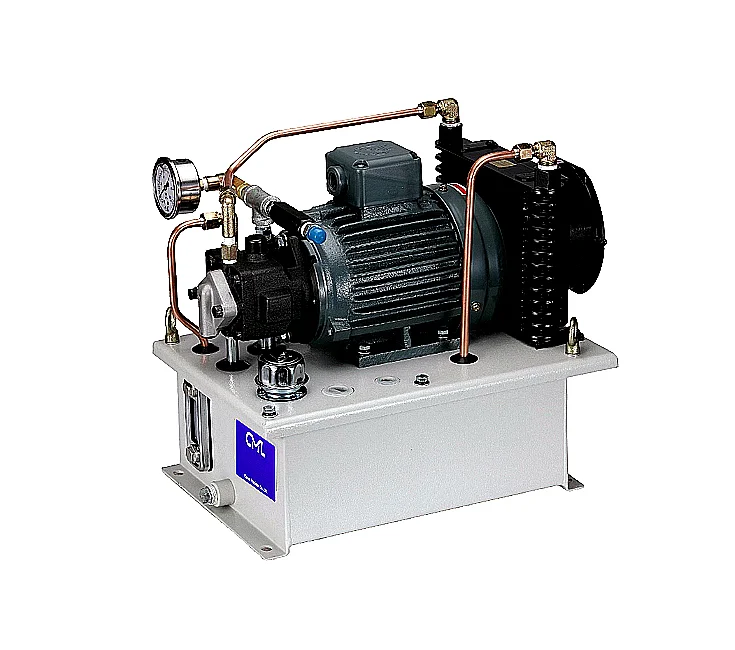

Servo system, Injection Molding Machine, Press Machine, Shearing Machine, Folding Machine, Test Machine, High Pressure Hydraulic Unit/ High Pressure Hydraulic Station.

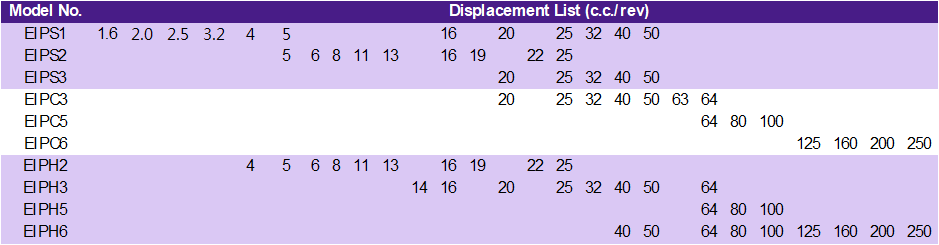

Displacement List

CML supplies Eckerle Hydraulic products in Asia include EIPS, EIPC, and EIPH series. Through the resource of both CML and Eckerle, a more diversified combination of products, such as IGP + EIPC and EIPH + IGP internal gear pump customization service. Eckerle pump displacement list as above, if you need any assistance please contact CML

- Gallerys

- Download

CML X Eckerle | Award-Winning Hydraulic Pumps & Valves – CML: Certified, Trusted, and Proven Worldwide

Located in Taiwan since 1981, Camel Precision Co., Ltd. is a hydraulic pumps and hydraulic valves manufacturer in Machinery and Equipment Manufacturing Industry.

In 1981 Camel Precision Co.,Ltd was founded. The management of company fully awards of high quality products requires not only sophisticate machinery, But good knowledge in technology is also important as well. Company invited senior engineers from Germany and Japan to lead the manufacturing and training of local engineers in hydraulic industry. We offer our customers industrial pumps, solenoid directional control valves, hydraulic pumps, vane pumps, external gear pump, internal gear pump, directional valve, hydraulic valves...etc.

CML, Camel Hydraulic, Camel Precision has been offering customers high-quality Vane Pump, Variable Displacement Vane Pump, Internal Gear Pump, Eckerle Asia Agent, External Gear Pump, Solenoid Valve, Modular Valve, Pressure Reducing Valve, Flow Control Valve, Hydraulic Valve since 1981, both with advanced technology and 38 years of experience, CML, Camel Hydraulic, Camel Precision ensures each customer's demands are met.

Company Facts in Numbers

0

Years of industry experience

0

Number of clients served

0%

Customer repurchase rate