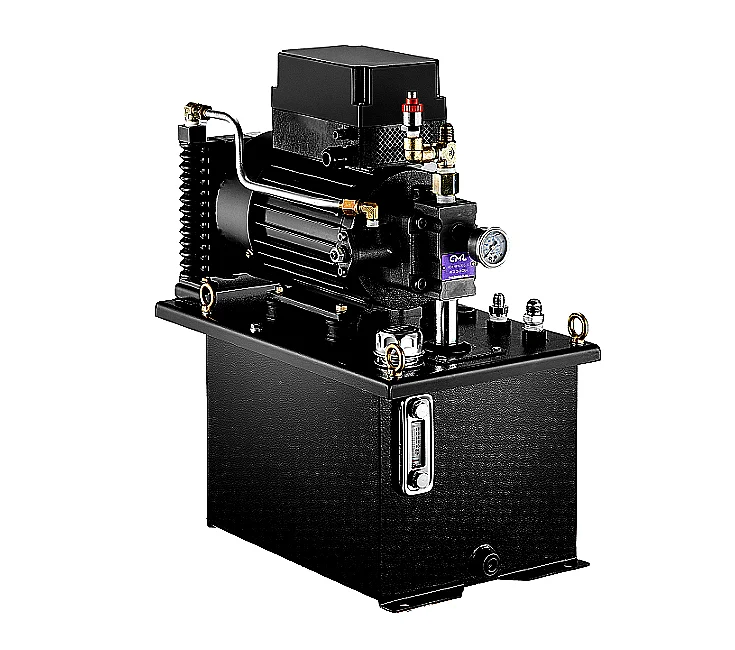

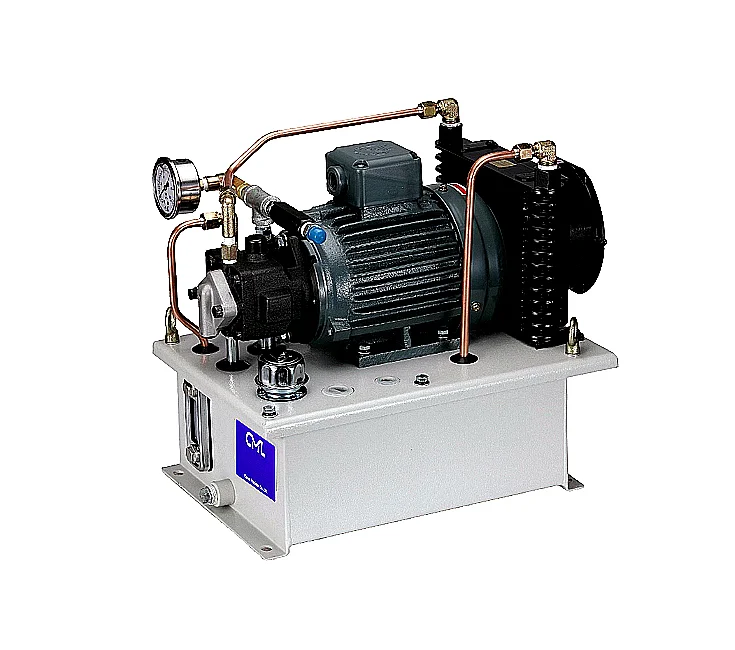

HPU Series Energy-saving Hybrid Power Unit

HPU

HPU Series, VCM-SFN, VCM-SFC, Customized products

The CML HPU Series Energy-Saving Hybrid Power Unit is designed to maximize energy efficiency. By leveraging hybrid inverter technology, it achieves a significant 40-60% reduction in energy consumption while maintaining constant pressure. This not only decreases noise levels but also enhances the overall working environment.

Furthermore, HPU series keeps the oil temperature within 2.5°C of ambient temperature, minimizing thermal expansion and ensuring high-precision control for consistent and smooth part processing. This not only prolongs the lifespan of hydraulic products but also significantly reduces installation space and hydraulic oil consumption.

By combining energy efficiency, environmental friendliness, and high performance, the HPU Series offers a sustainable and cost-effective solution for various industrial applications, and in August 2025, it won the Silver Recognition in the “1st Energy Efficiency Award.”

Media Gallerys

- CML Variable Vane Pump with Built-in Check Valve SFC, Compact Variable Displacement Vane Pump with Check Valve SFN Flat Key Shaft.

- CML Variable Vane Pump with Built-in Check Valve SFC, Compact Variable Displacement Vane Pump with Check Valve SFN Attached surface.

- CML Variable Vane Pump with Built-in Check Valve SFC, Compact Variable Displacement Vane Pump with Check Valve SFN Nameplate surface.

Feature

- Energy Saving: Achieves up to 60% energy savings.

- High Efficiency: Provides 100% stable pressure even at low speeds.

- Low Noise: Improves environmental noise to 60dB.

- Stable Oil Temperature: Keeps the oil temperature within 2.5°C of ambient temperature.

- Space Utilization: Reduces tank size by 40-60%.

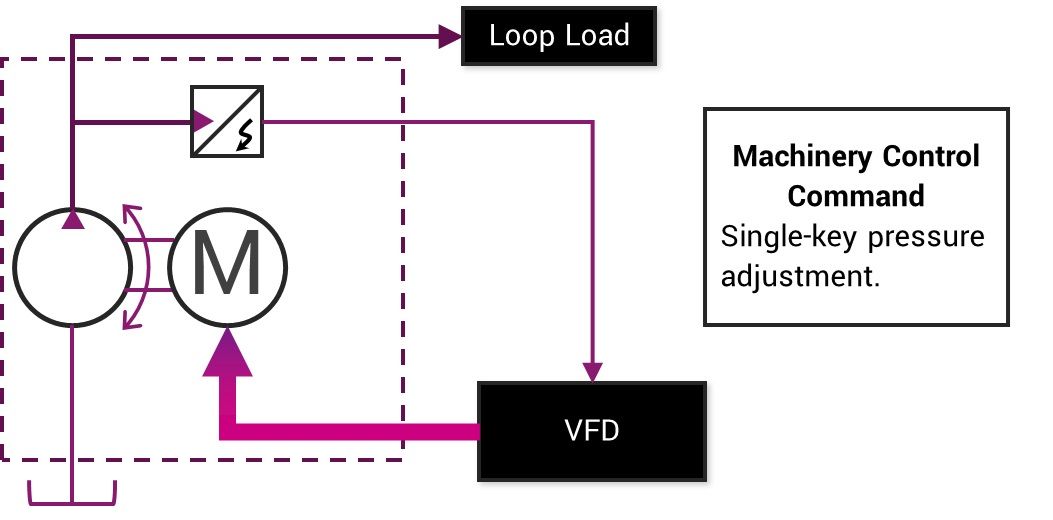

- Easy Installation: Ready to use after connecting the motor power line.

- Additional Safety Feature: The system can temporarily switch to traditional mode in case of external disturbances affecting the system, ensuring uninterrupted operation.

- Cost Savings: Reduces the specification requirements for cooling systems, saves oil and electricity.

Application

- Used for applications requiring long-term or stable pressure.

- Machine Tool Industry: Lathes, Milling machines, Gantry milling machines, Turn-mill centers, Five-axis machines, Band saw machines, Circular saw machines, Sawing machines, Vertical lathes, Vertical machining centers.

- Metal forming machine

- Packing machine

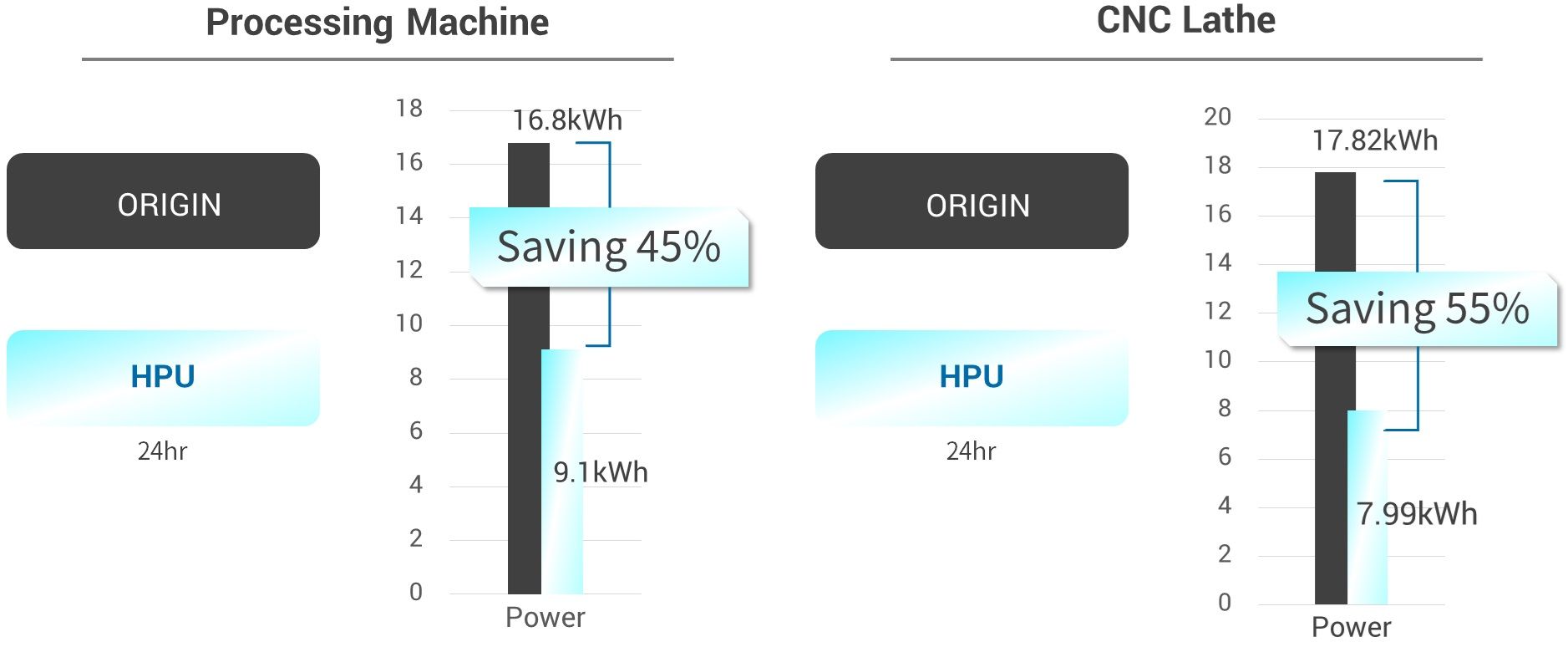

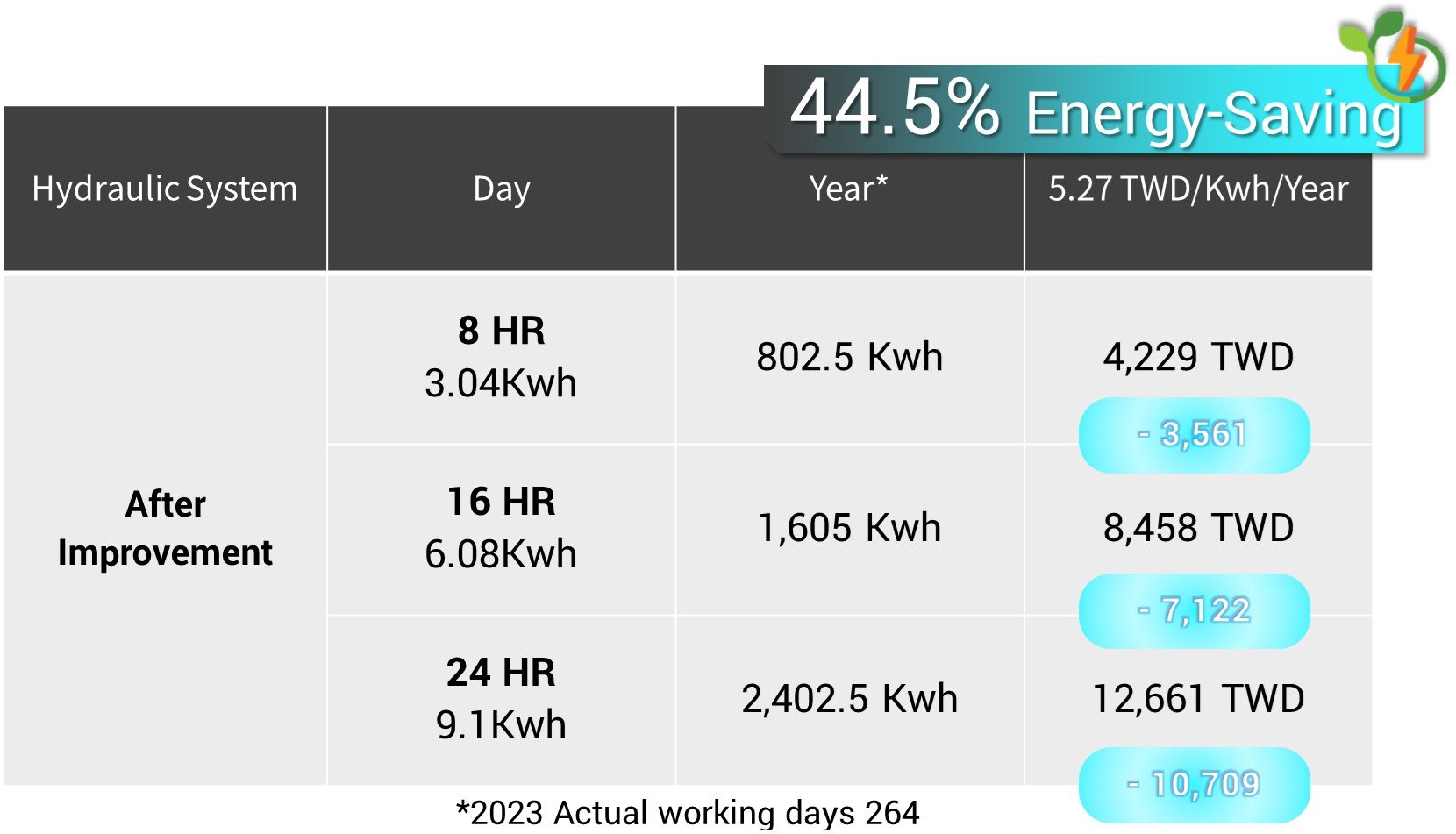

Power Consumption Comparison of Hydraulic Systems

In these cases, CML team's evaluation indicates that the inverter can meet the machine's performance requirements, resulting in a significant boost in production efficiency. If you have any requests for variable vane pumps, solenoid valves, hydraulic valves and power unit circuit design, please contact CML sales staff.

CNC Lathe

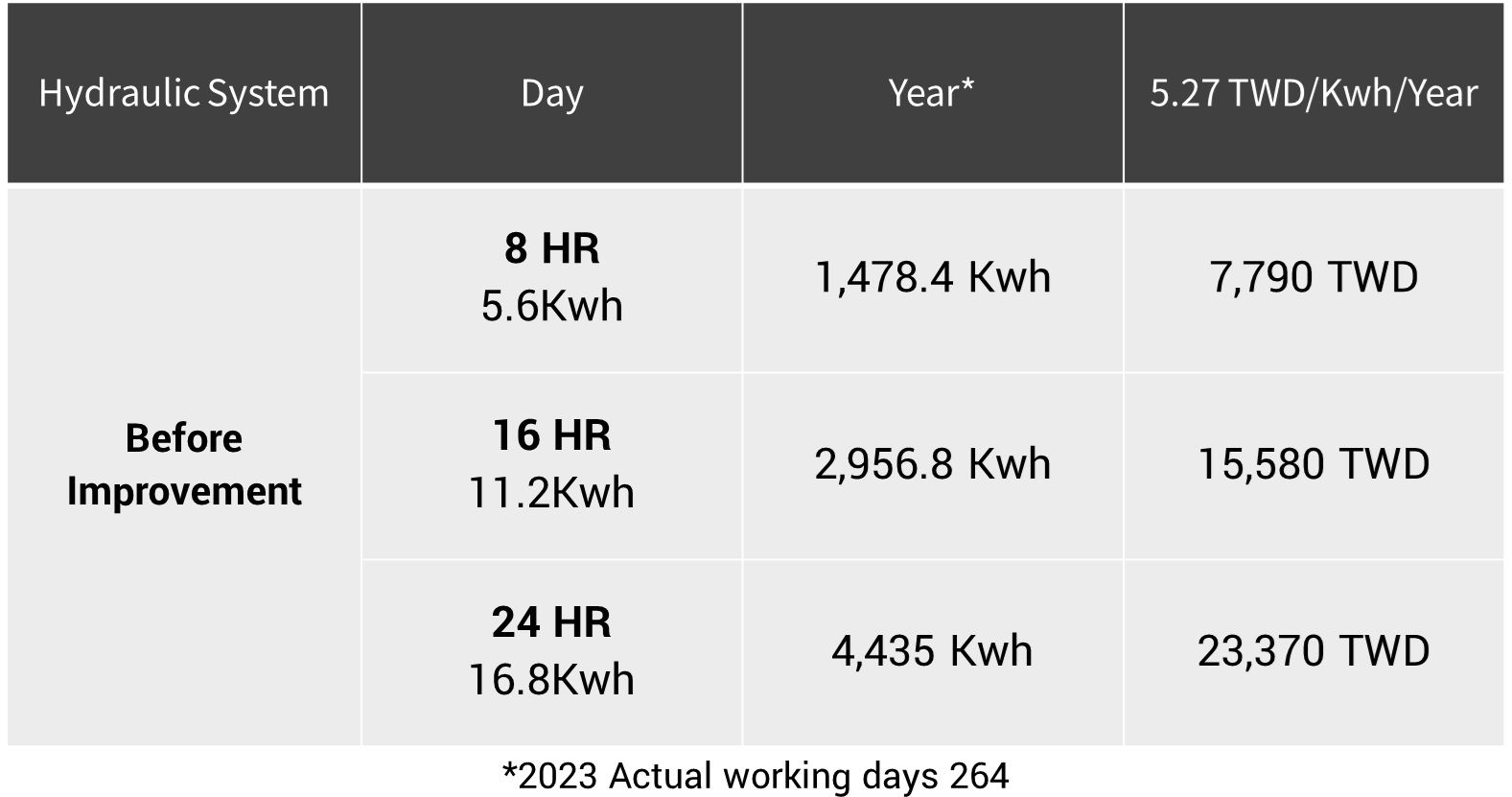

Hydraulic Energy Consumption "Before Improvement"

Energy-Saving Hydraulics "After Improvement"

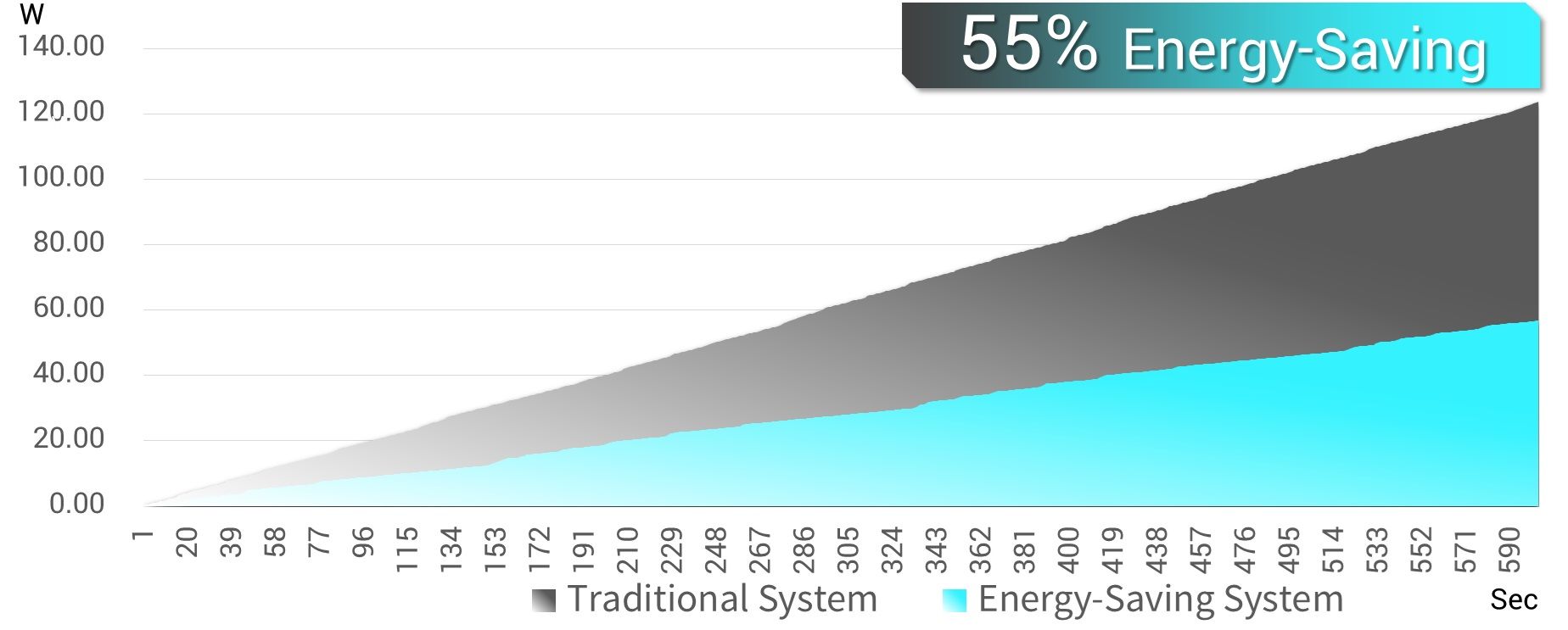

Achieve 55% energy saving by reducing motor to 2HP with inverter.

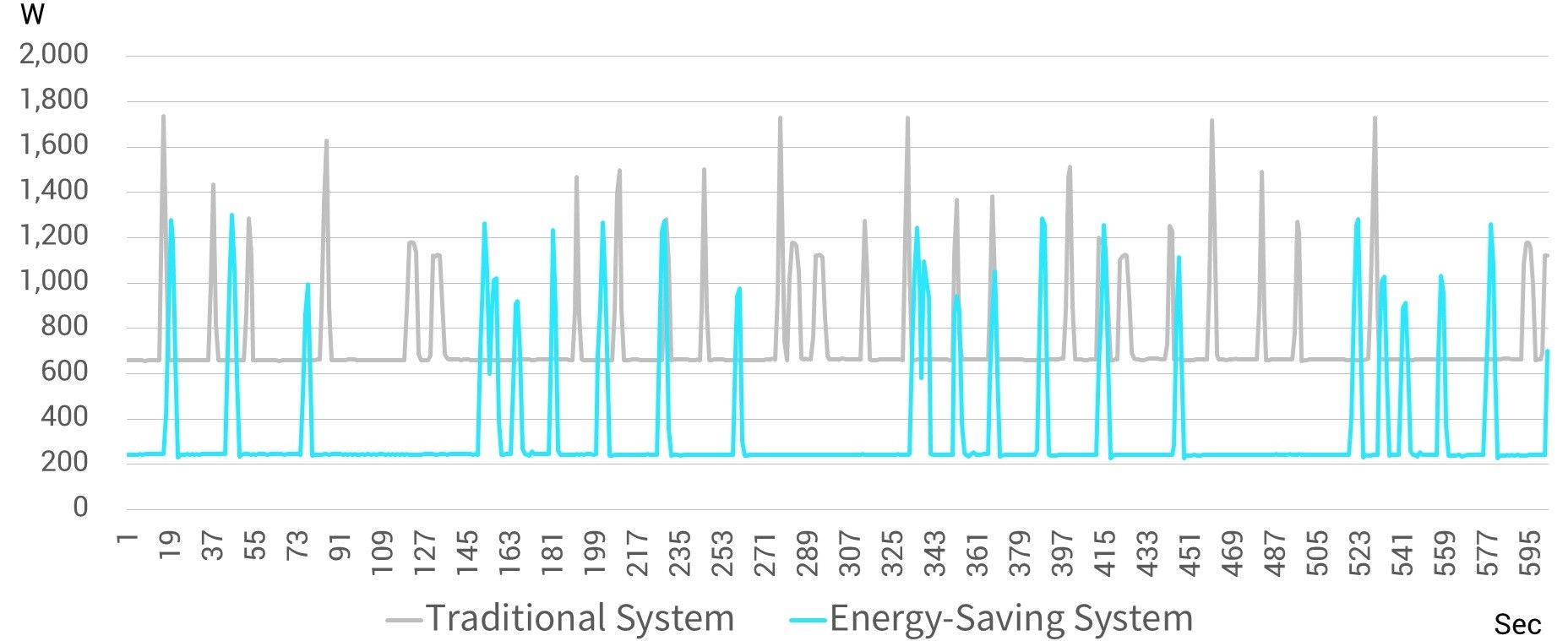

Comparison of " Instantaneous" Power Consumption

" Cumulative" Power Consumption Chart of CNC Lathe

Using inverter to adjust Motor speed allows us to decrease the flow rate and save energy.

- Data

Technical Data

- Chart

Performance Curve

- Notice

Energy-Saving Control System

Notice

- Related Products

Medium & low-pressure air-cooled coolers

AF0510-A2, AF-0510T-CA2, AF0510S-CA2, AL404T-CA2, AL608T-CA2, AL608T, AL404T,

The Medium & low-pressure type coolers are suited for use on a variable vane pump hydraulic system, in which its motor is not bigger than 3HP and the system pressure does not exceed 70 bar, to cool the heated...

DetailsMedium pressure air-cooled coolers

AW0607, AW0607-CA2, AW408-CA2, AW408R-CA2, AW0608-CA2, AW0608L-CA2

The Medium-pressure type coolers are suited for use on a variable vane pump hydraulic system, in which its motor is not bigger than 3HP and the system pressure does not exceed 70 bar, to cool the heated...

DetailsMedium & high-pressure air-cooled coolers

AH630-CA2, AH0608T-CA2, AH0608LT/RT, AH1012-CA2/3, AH1215-CA2/3, AH1418-CA2/3, AH1470-CA2/3, AH1428-ca2/3, AH1680-CA2/3

The Medium & high type coolers are suited for use on a variable vane pump hydraulic system, in which its motor is not bigger than 3HP and the system pressure does not exceed 70 bar, to cool the heated...

DetailsVariable Vane Pump with Built-in Check Valve SFC

VCM-SFC-24C-10, VCM-SFC-30C-10, VCM-SFC-40C-10

Variable Displacement Vane Pump with Built-in Check Valve is easy to be equipped with manifold block. The manifold block can be directly installed at the oil pump outlet, and one to multiple circuit valve...

Details

HPU Series Energy-saving Hybrid Power Unit | EMC, ISO 9001, and CE Certified Hydraulic Valves – CML’s Global Recognition

Located in Taiwan since 1981, Camel Precision Co., Ltd. is a HPU Series Energy-saving Hybrid Power Unit (model: HPU ) manufacturer in Machinery and Equipment Manufacturing Industry.

In 1981 Camel Precision Co.,Ltd was founded. The management of company fully awards of high quality products requires not only sophisticate machinery, But good knowledge in technology is also important as well. Company invited senior engineers from Germany and Japan to lead the manufacturing and training of local engineers in hydraulic industry. We offer our customers industrial pumps, solenoid directional control valves, hydraulic pumps, vane pumps, external gear pump, internal gear pump, directional valve, hydraulic valves...etc.

CML, Camel Hydraulic, Camel Precision has been offering customers high-quality Vane Pump, Variable Displacement Vane Pump, Internal Gear Pump, Eckerle Asia Agent, External Gear Pump, Solenoid Valve, Modular Valve, Pressure Reducing Valve, Flow Control Valve, Hydraulic Valve since 1981, both with advanced technology and 38 years of experience, CML, Camel Hydraulic, Camel Precision ensures each customer's demands are met.

Company Facts in Numbers

0

Years of industry experience

0

Number of clients served

0%

Customer repurchase rate