ESG Cooling Solution

CML SPU Series Cooling Circulation Power Unit is designed to address three key challenges in today’s manufacturing: hydraulic iol overheating, limited space, and unstable machining precision. With up to 3× greater cooling efficiency than traditional systems, the SPU Series maintains optimal oil temperature without the need for oil chiller. By reducing oil temperature up to 20%, the system ensures thermal stability, boosts machining precision, extends component lifespan, and lowers energy use—resulting in more reliable, efficient operations. As industries shift toward sustainability, the SPU Series is your reliable partner in achieving energy efficiency, ESG goals, and net-zero emissions—without compromising on performance, and in August 2025, it won the Silver Recognition in the “1st Energy Efficiency Award.”

Why Choose CML’s Cooling Solution?- Eliminates core issues such as oil overheating, space constraints, and unstable machining precision.

- Improves cooling efficiency 3× and lowers oil temperature by 20% with CML variable vane pump with cooling circulation pump, boosting productivity and reliability.

- After expert evaluation, no high-power oil chiller required—optimized system design ensures stable oil temperature and energy savings.

- Supports companies in achieving ESG goals and progressing toward net-zero carbon emissions.

Why Worry About Rising Hydraulic Oil Temperature?

As industrial machinery and technology advance, the economic value of high-precision machining continues to rise. Greater accuracy reduces material waste and boosts product competitiveness. At the same time, efficient machine space usage impacts oil tank design, material consumption, and customization flexibility—all contributing to sustainable manufacturing aligned with global ESG and net-zero goals.

Sustainability is no longer a future goal—it’s a current priority. Since 2022, ESG trends have driven over 70% of new machines to adopt energy-efficient designs, with more companies investing in sustainable components early in development.

One major factor is oil temperature control. Excessive or unstable oil heat can shorten component life, deform parts, and reduce machining precision—leading to waste and higher costs. Traditional fixes like enlarging oil tanks or adding chillers increase energy use and system size, undermining sustainability.

Active liquid cooling now offers a smarter alternative—lowering and stabilizing oil temperature without enlarging tanks or using power-hungry chillers. It improves precision, extends system life, and helps manufacturers meet ESG and carbon reduction targets efficiently.

VCM+CG Cooling Circulation Pump and

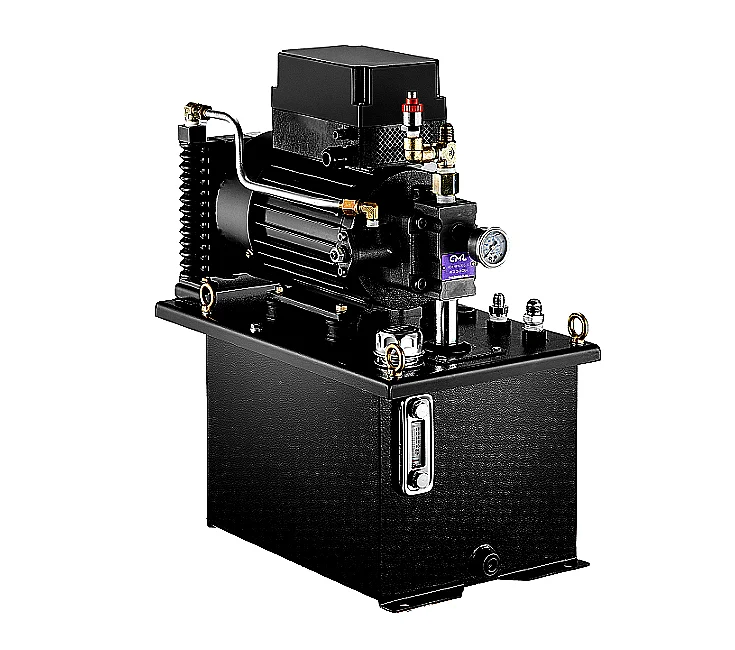

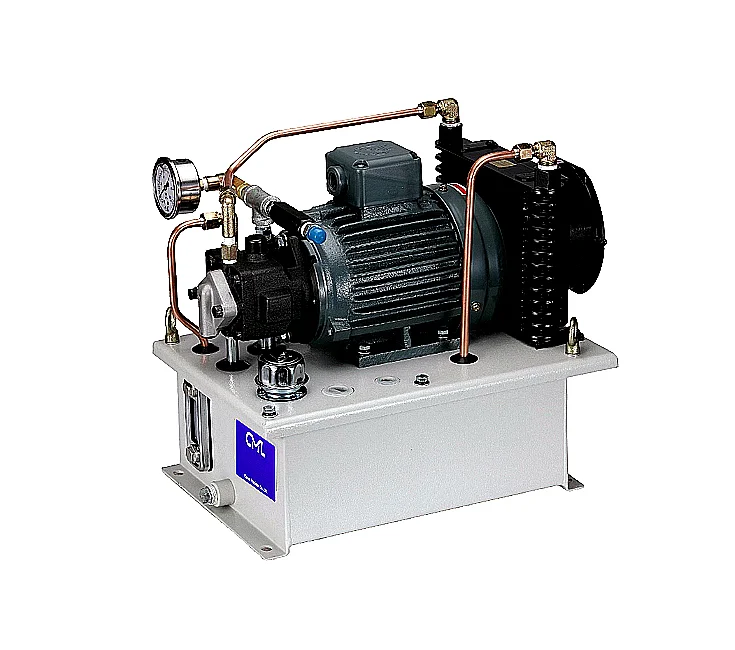

SPU Series Cooling Circulation Power Unit

As modern equipment evolves toward high precision, thermal error has become one of the leading causes of quality defects—accounting for up to 40%–70% of total production errors. In response, precise and efficient temperature control has emerged as a core requirement for competitive manufacturing.

CML has been deeply engaged in the hydraulic systems industry for many years, accumulating extensive experience through both domestic and international collaborations. We continue to support customers in developing customized hydraulic stations and systems. Through market feedback and hands-on field insights, we have observed a growing demand for advanced oil temperature control solutions.

To address the series of issues caused by oil temperature, CML developed the patented VCM+CG Variable Vane Pump with Cooling Circulation Pump ****after extensive testing to tackle oil temperature issues. This system improves cooling efficiency through optimized design. We offer full support from installation to after-sales service. Proven by many clients, it reduces oil temperature by up to 20%, enhancing machining accuracy, reducing rework, saving materials, and lowering production costs while increasing product competitiveness.

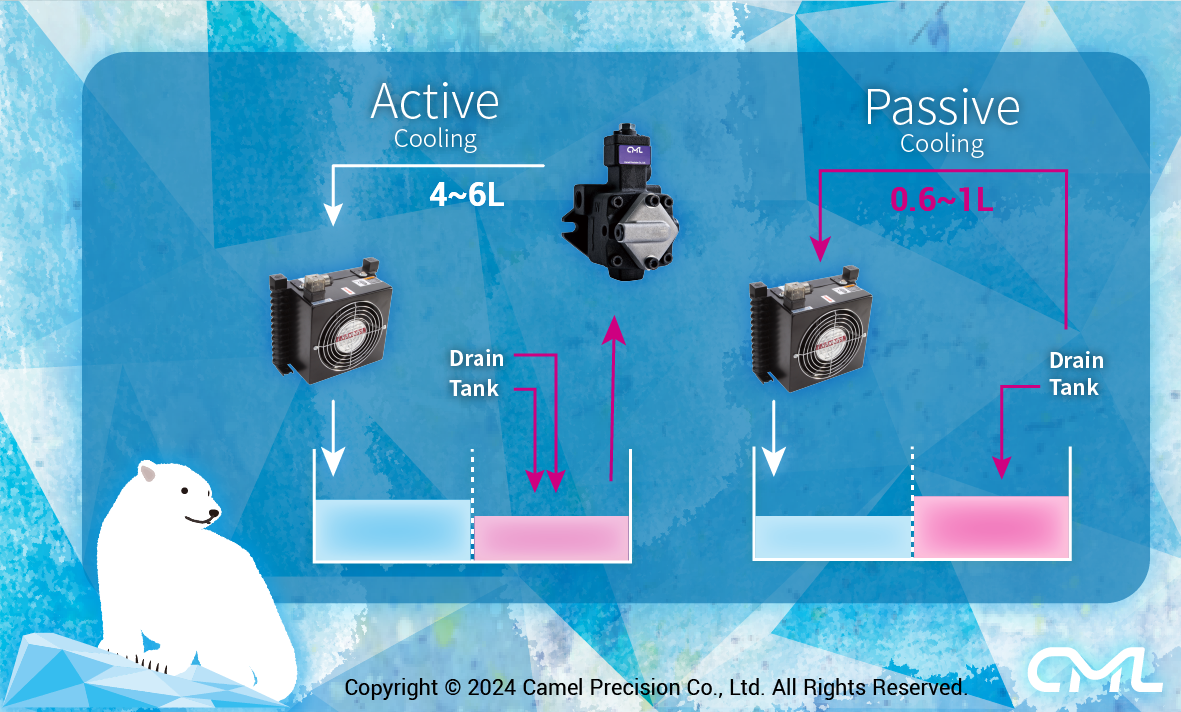

Active vs. Passive Liquid Cooling

Traditional hydraulic power units with standard vane pump typically use a passive liquid cooling method. During operation, the heat generated is dissipated through a small amount of internal leakage oil (approximately 600 to 1,000 c.c. per minute) that is directed to a cooling device before returning to the oil tank.

In contrast, the VCM+CG Variable Vane Pump with Cooling Circulation Pump employs an active liquid cooling method. Utilizing the continuous output characteristic of the circulation pump, the system actively directs a large volume of hot oil to the cooling system based on heat calculations. This approach matches the pump's displacement with the cooler's heat dissipation capability, ensuring stable temperature control.

Compared to active liquid cooling, passive liquid cooling is less effective in solving thermal deformation caused by excessive oil temperature. In the VCM+CG system, the internal leakage and heat generated during machine operation channel into a designated hot oil zone in the oil tank. With a flow rate of 4 to 6 liters per minute, the circulation pump efficiently transfers this hot oil to the cooler for heat dissipation.

Unlike traditional oil tank designs, the new hydraulic power unit paired with the VCM+CG system doesn't rely on increasing the tank's surface area for passive heat dissipation. Instead, the tank's volume is reduced to just one times the pump's per-minute flow rate. This design innovation decreases the oil tank space to approximately 30% of the original size, significantly reducing the using amount of hydraulic oil and extending its service life, ultimately lowering costs.

Due to these advantages, active liquid cooling is widely used in high-precision, long-operating machines, such as CNC machine tools and shoe manufacturing machinery.

5 Key Features of SPU Series

1. High-Efficiency Cooling:

The SPU series offers cooling performance that exceeds traditional methods by over three times, thanks to the continuously outputting of circulation pump. This not only prevents overheating but also stabilizes oil temperatures, reducing the risk of damage to hydraulic components and extending their lifespan.

2. Optimized Space Utilization:

The SPU series from CML reduces the need for space dedicated to oil tank surface cooling. The oil tank volume can be decreased from 3.5 times to 1.5 times the pump's per-minute flow rate, saving valuable equipment space.

3. Cost Savings:

The reduction in oil tank volume and the stabilization of oil temperature result in lower material costs. This is achieved by reducing the raw materials needed for oil tank and machine production, as well as decreasing the using amount of hydraulic oil.

4. Extended Lifespan:

By lowering and stabilizing oil temperatures, the SPU series helps prolong the life of hydraulic components and extends the effective usage time of hydraulic oil, leading to reduced maintenance and replacement costs.

5. Temperature Control:

Improved Machining Precision: Through the CML team’s meticulous matching of pump displacement and cooler heat dissipation capacity, the SPU series achieves stable temperature control. This effectively manages oil temperatures, minimizing the impact of thermal deformation on equipment and materials, thus enhancing machining precision and stability.

The application of VCM+CG in hydraulic systems brings numerous advantages, including high-efficiency cooling, temperature stability, space savings, cost reduction, extended component life, and improved machining precision. As environmental consciousness grows, this provides companies with a superior solution.

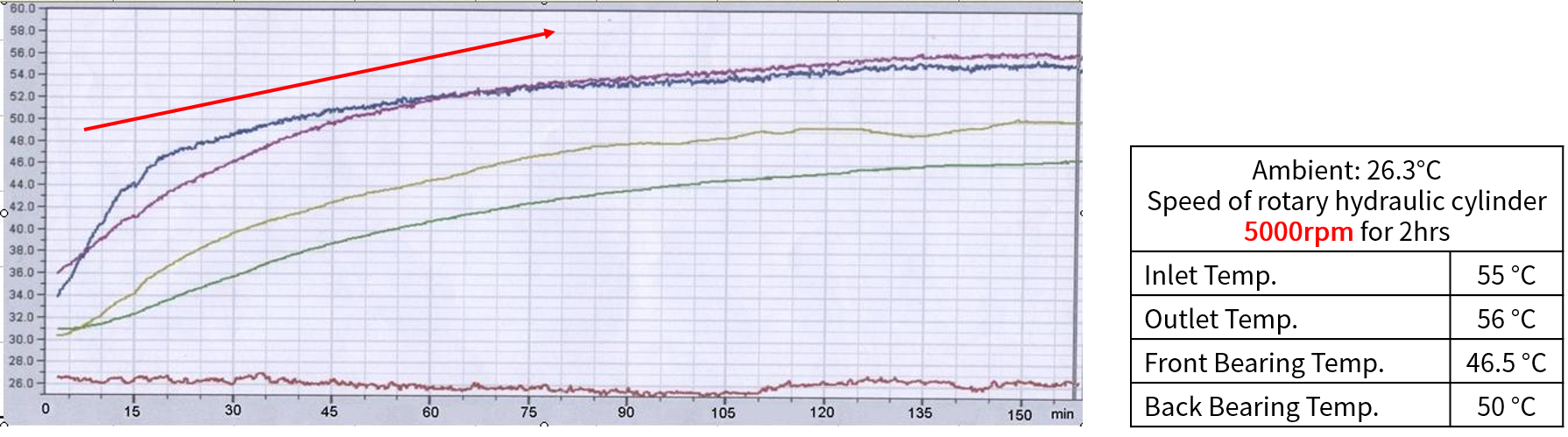

High-Efficiency Oil Temperature Control Curve

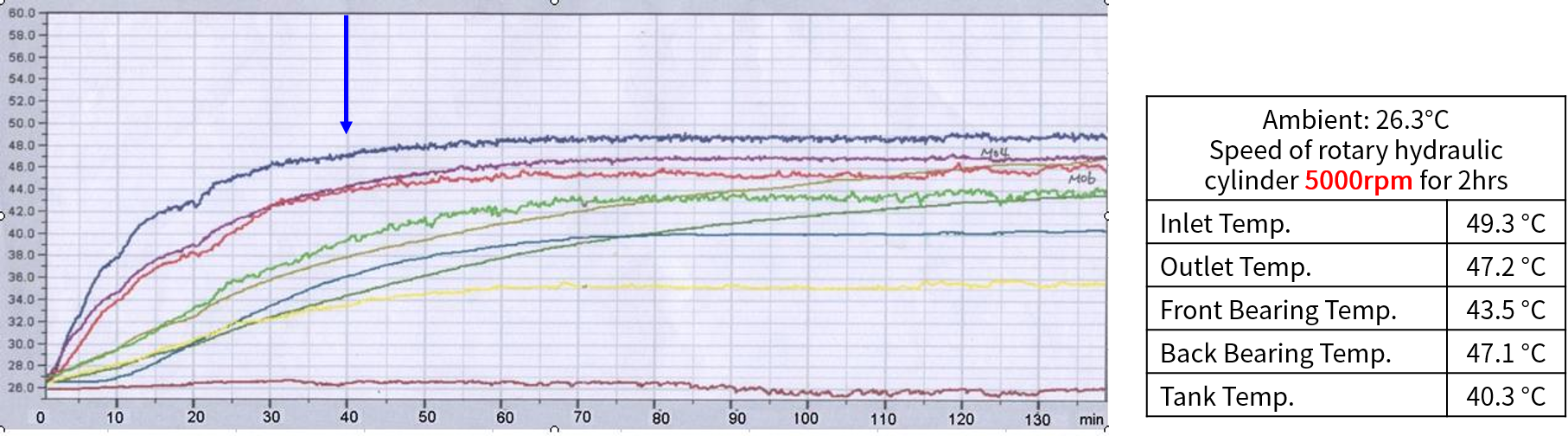

Standard Variable Vane Pump (Passive Liquid Cooling) with Cooler

When using a standard variable vane pump with passive liquid cooling and a cooler, the oil temperature gradually increases due to the continuous operation of machine. Over time, this rise in temperature can cause the hydraulic oil to degrade and lead to thermal deformation of the equipment, ultimately reducing the machine's lifespan and economic efficiency.

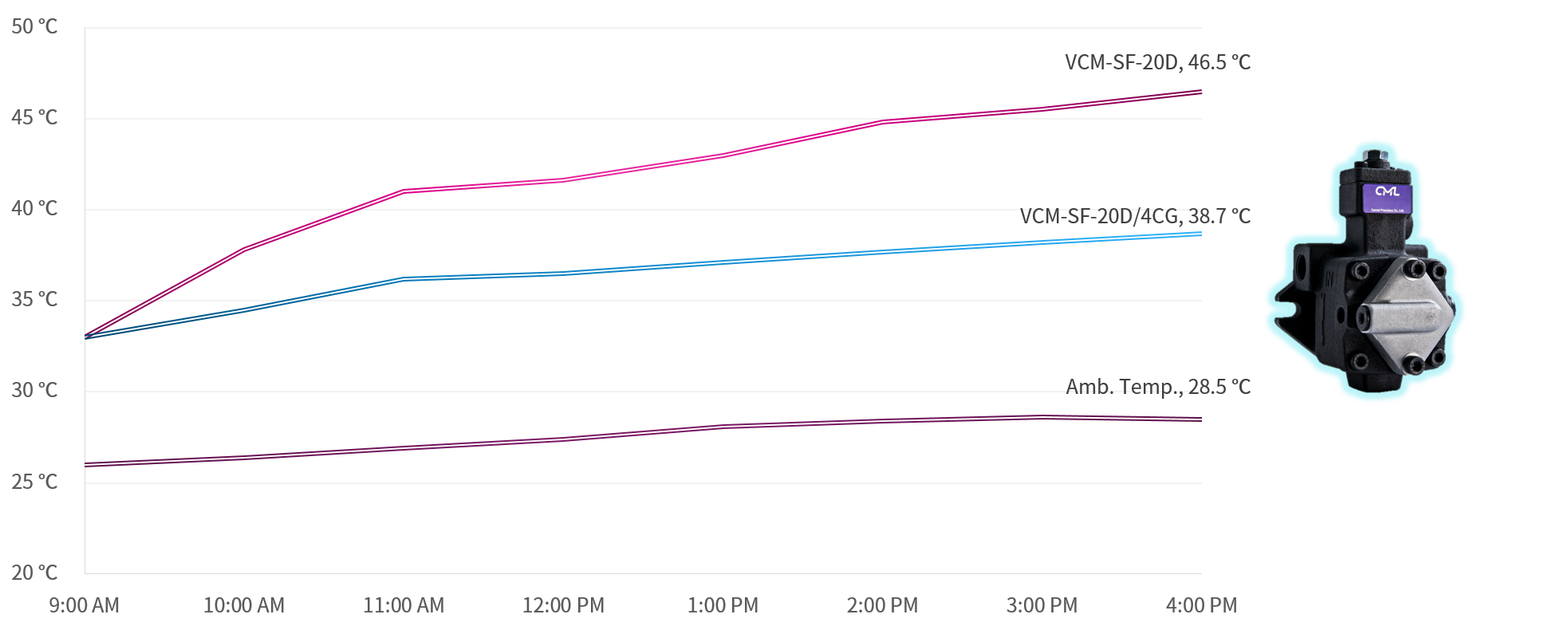

Variable Vane Pump with Cooling Circulation Pump

(Active Hydraulic Cooling) VCM+CG with Cooler

Under the conditions of a rotary hydraulic cylinder running at 5,000 rpm with the VCM+CG system, the oil temperature stabilizes within 40 minutes of the machine's startup and ceases to rise. Additionally, the spindle bearing temperature decreases by 3°C, resulting in minimal thermal displacement of the front and rear bearings, thereby ensuring consistent product machining precision.

From the comparison chart, it can be seen that the Variable Vane Pump with Cooling Circulation Pump (VCM+CG) stabilizes the oil temperature within just 2 hours of startup.

What are you waiting for?

As industrial machinery and technology advance, the economic value of high-precision machining continues to rise. Greater accuracy reduces material waste and boosts product competitiveness. At the same time, efficient machine space usage impacts oil tank design, material consumption, and customization flexibility—all contributing to sustainable manufacturing aligned with global ESG and net-zero goals.

Sustainability is no longer a future goal—it’s a current priority.

Since 2022, ESG trends have driven over 70% of new machines to adopt energy-efficient designs, with more companies investing in sustainable components early in development.

One major factor is oil temperature control. Excessive or unstable oil heat can shorten component life, deform parts, and reduce machining precision—leading to waste and higher costs. Traditional fixes like enlarging oil tanks or adding chillers increase energy use and system size, undermining sustainability.

Active liquid cooling now offers a smarter alternative—lowering and stabilizing oil temperature without enlarging tanks or using power-hungry chillers. It improves precision, extends system life, and helps manufacturers meet ESG and carbon reduction targets efficiently.

CML Camel Precision:

A Company Committed to Sustainable Energy for Humanity

CML Camel Precision has 43 years of experience in the production and sale of hydraulic products. As the first domestic company to enter the hydraulic manufacturing industry and produce internal gear pumps, we serve nearly 3,000 enterprises across 66 countries worldwide, working with over 180 suppliers. Our deep technical expertise and knowledge of the hydraulic industry, combined with rich experience in cross-border and cross-enterprise technical collaborations, position us as a leader in the field.

CML offers eight major categories with more than 500 types of pumps and valves, boasting 12 product patents. Our products undergo rigorous testing, including dedicated test benches, data analysis, durability tests, and noise tests. Systematic and digitalized quality control ensures the reliability of our products. Our services extend across various industries, including footwear manufacturing machinery, machine tools, plastic and rubber machinery, metal processing machinery, and mobile machinery. By deeply understanding our clients' industries and product needs, our professional team collaborates with customers to design and plan customized hydraulic power units, providing a complete process from installation and testing to after-sales service.

In terms of ESG (Environmental, Social, and Governance), CML Camel Precision is committed to being a company that helps humanity achieve sustainable energy. We develop high-efficiency green solutions to meet market demands and work with our customers to create a sustainable future. As a key driver of innovation, CML has developed patented products like the VCM+CG variable vane pump with cooling circulation and the SPU series cooling circulation hydraulic power units. These products can reduce temperatures by an average of 20%, effectively enhancing manufacturing precision and production efficiency, reducing material waste, saving production costs, and improving product competitiveness.

With exceptional product quality and professional service, CML has become a trusted partner for customers, providing stable and reliable power while leading them towards shared success.

- Related Products

Medium & high-pressure air-cooled coolers

AH630-CA2, AH0608T-CA2, AH0608LT/RT, AH1012-CA2/3, AH1215-CA2/3, AH1418-CA2/3, AH1470-CA2/3, AH1428-ca2/3, AH1680-CA2/3

The Medium & high type coolers are suited for use on a variable vane pump hydraulic system, in which its motor is not bigger than 3HP and the system pressure...

Details

ESG Cooling Solution | Award-Winning Hydraulic Pumps & Valves – CML: Certified, Trusted, and Proven Worldwide

Located in Taiwan since 1981, Camel Precision Co., Ltd. is a hydraulic pumps and hydraulic valves manufacturer in Machinery and Equipment Manufacturing Industry.

In 1981 Camel Precision Co.,Ltd was founded. The management of company fully awards of high quality products requires not only sophisticate machinery, But good knowledge in technology is also important as well. Company invited senior engineers from Germany and Japan to lead the manufacturing and training of local engineers in hydraulic industry. We offer our customers industrial pumps, solenoid directional control valves, hydraulic pumps, vane pumps, external gear pump, internal gear pump, directional valve, hydraulic valves...etc.

CML, Camel Hydraulic, Camel Precision has been offering customers high-quality Vane Pump, Variable Displacement Vane Pump, Internal Gear Pump, Eckerle Asia Agent, External Gear Pump, Solenoid Valve, Modular Valve, Pressure Reducing Valve, Flow Control Valve, Hydraulic Valve since 1981, both with advanced technology and 38 years of experience, CML, Camel Hydraulic, Camel Precision ensures each customer's demands are met.

Company Facts in Numbers

0

Years of industry experience

0

Number of clients served

0%

Customer repurchase rate